Me:

The making of ...

My Links

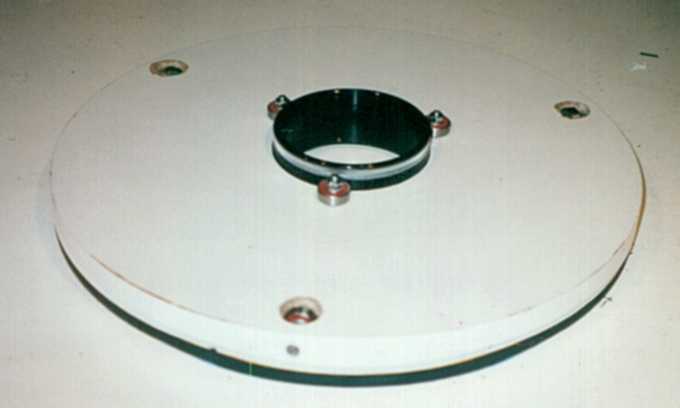

Fig 1: Putting the base together

The flange used to be a part of a medical vision system. Or at least I think it was. I found it on a junkyard. It had lots of optics, a big photomultiplier tube ( broken) and electronics. The lenses were worthless for astronomical purposes.

The mechanics are top quality.

Fig 2: Smoothing the circumferenceThe telescope base consists of 2 disks on top of each other. The top one has bearings keeping it centered round the flange and 3 bearing assuring easy rolling on the bottom disk. The bottom disk is made of bakelite. This material is waterproof, very stable and hard. Expensive kitchen- and bathroom closets are made of it.

Fig 3 : Smoothing

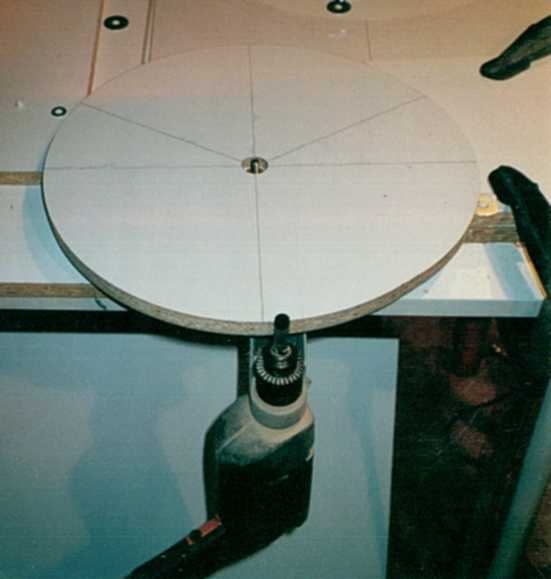

Fig 4: Cutting teethAdopted to Bob Norgard's idea on cutting teeth I'm using a M6 tap f resulting in 354 teeth along the circumference of the aluminum flange.

Fig 5: Teeth cutting set-up

The tap is put into the drilling machine. The flange can rotate freely on the support pushed firmly against the ball bearing.

Fig 6: Cutting teeth detail.

About 50 turns of the flange were needed to cut the teeth to an acceptable depth.To be continued ....

- Next Yahoo! group is a forum to discuss topics related to Mel Bartels' computerized telescope control system.

Click to subscribe to scope-drive

Telescope Making

Web RingNext | Previous | Random | List Sites

Next 5 | Previous 5 | Join